Proud to offer over thirty years of outstanding services and operations.

Aalberts surface technologies-accurate brazing is a full-service vacuum brazing and thermal processing enterprise with over 30 years in the business. Over that time, we’ve become adept at heat treating materials that include stainless steel, super alloys, copper, and refractory materials.

In 2020 we expanded our technology to include Hot Isostatic Pressing (HIP) services, due to an increasing need for perfect parts for demanding industries including aerospace, additive manufacturing, medical, and casting. Our Nadcap certified facility in Greenville, South Carolina anchors HIP services in the US.

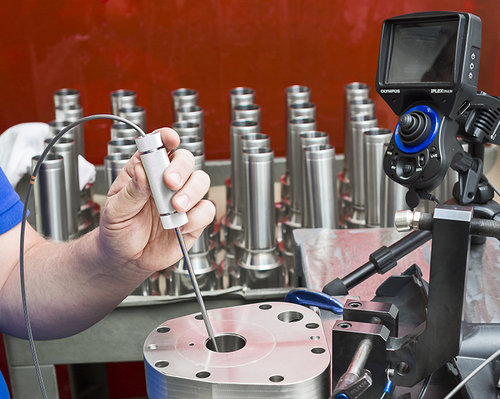

Vacuum brazing specialties include honeycomb seals for both OEM and repair, as well as end-cover, nozzle, and cartridge assemblies for fuel delivery systems. We also process heat exchangers, tube assemblies, medical implants, consumable welding products, and semiconductor equipment.

We braze and/or heat treat various materials including:

We have also had great success heating treating A, D and M series tool steels.

Vacuum heat treating allows for uniform heating and cooling which minimizes distortion and provides excellent metallurgical properties.

Unlike competitors, we have the unique expertise, capacity, and equipment to take new programs and get them into production quickly.

Sign up with your email address to receive more information, news or updates. We respect your privacy.

"*" indicates required fields